PNEUMATIC SYSTEMS

For years, pneumatic systems have provided an important role in the technology of mechanical work. Utilizing compressed air instead of hydraulic fluid, pneumatic systems can transmit and control energy throughout the mechanical system as a whole. Pneumatic systems offer a variety of different advantages that allow them to remain effective, reliable, and even environmentally friendly for businesses.

- 100% Aluminum & 100% Customizable

- The most comprehensive and compact range on the market.

- Wide variety of products available: sizes ranging from 1/2” - 4”.

- (3) Colors of pipe, numerous configurations of fittings Compact, lightweight and resistant pipes and fittings

- Easily identifiable: color coded pipe, clearly marked with product information, no room for error

- Quick and easy to install. Can be pressurized immediately. Simplified network extensions, no need of special tools.

- Clean air supply, free from debris, thanks to the perfectly smooth internal pipe surface in aluminum, optimized flow rate.

- 100% leak free guarantee: zero leaks and easy connection of the pipe into the fitting due to the “PPS Grip.”

- New contoured and lubricated seal - internal parts cannot detach from the body after assembly

- Compatible with compressor oils

- Impact strength

New Paragraph

New Paragraph

Design & Engineering

At D & R Hydraulic Services, LLC. we offer complete air systems to meet your needs as well as parts and service from fabrication to installation.

Air Compressor Repair

- Repairs on most brands of Air Compressors

- Stocking parts for Quincy, Saylor Beall and Atlas Copco

THE EXPERTS AT D & R HYDRAULIC SERVICES IN LEOLA, PENNSYLVANIA, CAN HELP YOU REPAIR AND MAINTAIN ANY MECHANICAL DEVICE THAT UTILIZES PNEUMATIC SYSTEMS QUICKLY AND EFFICIENTLY. CALL US TODAY AT 717-656-0525 FOR MORE INFORMATION ABOUT OUR SERVICES.

Click For More Information Regarding Pneumatic Systems:

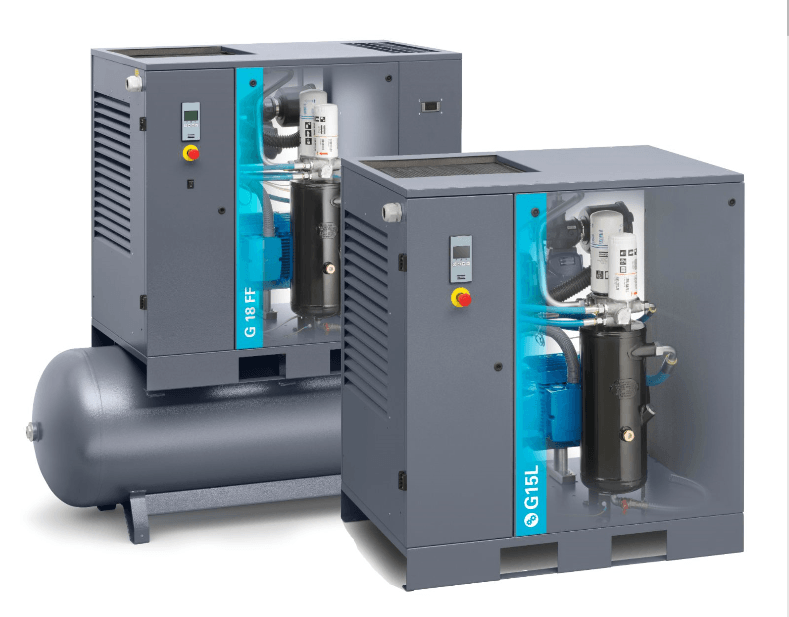

Built-in reliability

• Atlas Copco’s patented rotary screw element allows for a 100% duty cycle.

AIR TREATMENT,

A CRUCIAL INVESTMENT

THE BENEFITS ADD UP

• Strong performance.

• Pressure dew point display.

• Straightforward reliability.

• Easy installation.

• Minimal maintenance.

• Significant cost savings.

VSD+ for 50% average energy savings

Monitor performance

and productivity

With AIRkeeper you can remotely control

your compressor and optimize its efficiency

The Prevost Piping System range ensures :

• A clean and good-quality air supply

• A leaktight network and optimised flow rate

• An operating pressure of 232 psi.

Where are air compressors used?

Amounting to as much as 12% of all industrial electricity usage, air compressors are a silent partner to every industry imaginable. Compressors are used by your dentist. There is an air compressor in every cement plant, in every wastewater treatment facility, in every power plant.

From powering pneumatics in production lines, to spraying paint, to blowing glass and thermoformed plastics, to aerating the water supplied to our taps, there is a compressor somewhere that is supplying the compressed air needed to make almost everything we touch.

Why choose an Atlas Copco air compressor?

Reliable air compressors

The continuity of your production matters to us as much as it matters to you. That is why Atlas Copco compressors are some of the most reliable machines you can get. Choosing an Atlas Copco compressor means choosing technology from a manufacturer that has been at the forefront of development in compressed air for more than 100 years.

Compressors with lowest total cost of ownership

Air compressors are long term investments that will play a significant part of your business for years to come. The average factory changes air compressors every 7-10 years, meaning that the initial capital expenditure is only a fraction of how much your compressor will cost you in total. It may surprise you to find out that 70% or more of your air compressor's lifecycle cost will come down to its energy usage.

Atlas Copco compressors have the lowest total cost of ownership, owing to ever-improving design and unmatched, energy efficient variable speed drive motors. That all adds up to a significantly reduced bottom line for you and your factory.

Our compressor installations are tailored for you

What is your greatest concern? Factory footprint? Having a quiet compressor? Good finance options for your equipment? Turnkey installation? Whatever is on your mind, you can be assured that our sales team will have it as a top priority in suggesting the right piece of equipment or installation for you. Be it that you need the lowest cost of investment because you are just starting out, or you need a foolproof compressed air installation with guaranteed uptime, our offer will meet your factory's needs. Speak to our team today to learn more.

Address: 137 Newport Rd Leola, PA 17540 | Phone: 717-656-0525 | Email: info@drhydraulicServices.com

Business Hours

- Mon - Fri

- -

- Saturday

- Appointment Only

- Sunday

- Closed